Karolo e Ntle ea boleng ba Ferro Silicon Bakeng sa ho Lahla

tshebediso

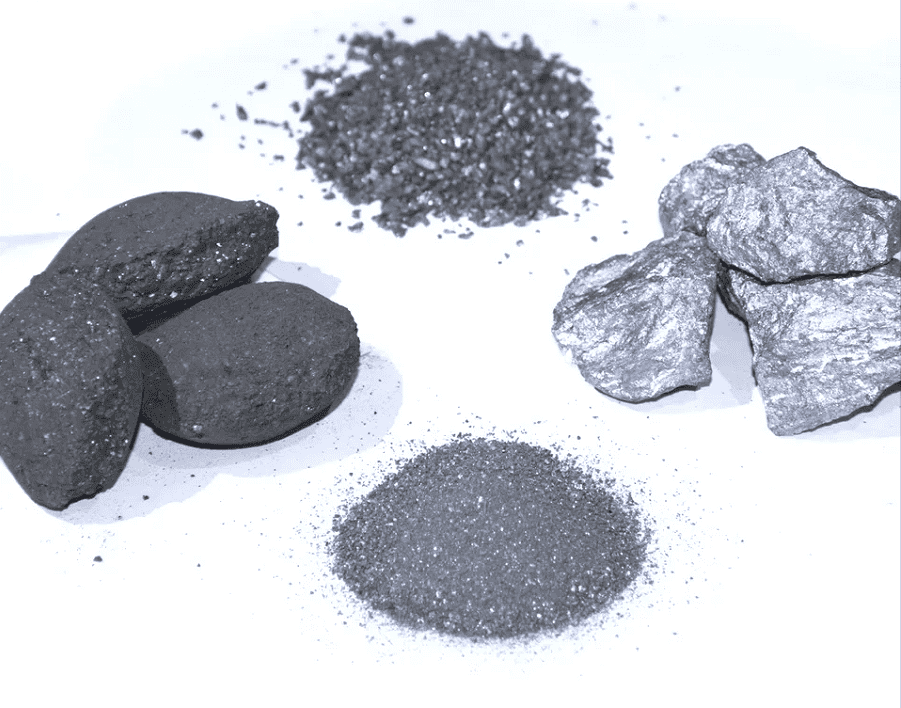

(1) Likaroloana tsa Ferro silicon li ke ke tsa sebelisoa indastering ea ho etsa litšepe feela empa hape e le lisebelisoa tsa tšepe tse sebelisoang hangata indastering ea tšepe e entsoeng ka tšepe.Sena se bakoa haholo ke hore likaroloana tsa ferro silicon li ka sebelisoa ke baetsi ba tšepe ea tšepe ho nka sebaka sa inoculants le spheroidizers.Ka indasteri ea tšepe e entsoeng ka tšepe, theko ea likaroloana tsa ferro silicon e tlase haholo ho feta ea tšepe 'me e qhibiliha habonolo, e leng se etsang hore e be sehlahisoa sa boleng bo phahameng ba tšepe e entsoeng ka tšepe.Boleng bo phahameng ba ferro silicon particle inoculant e nang le boholo ba likaroloana tse lekanang le phello e ntle ea inoculation nakong ea ho lahla e ka khothalletsa pula ea graphite le spheroidization, e leng se etsang hore e be lisebelisoa tse hlokahalang tsa metallurgic bakeng sa ho hlahisa tšepe ea ductile.

(2) E sebelisoa e le deoxidizer le alloying agent indastering ea ho etsa tšepe.Kamano ea lik'hemik'hale lipakeng tsa silicon le oksijene e kholo haholo, ka hona likaroloana tsa ferro silicon ke li-deoxidizer tse matla ha ho etsoa tšepe bakeng sa pula le ho ntša oxidation ea ho hasana.Lefapheng la ho etsa tšepe, hangata e sebelisoa e le sesebelisoa sa ho futhumatsa sekoaelo sa ingot ho ntlafatsa boleng le ho hlaphoheloa ha ingot ka ho sebelisa tšobotsi ea hore lijo-thollo tsa ferrosilicon li ka lokolla mocheso o mongata ho tloha ho ene e tukang mocheso o phahameng.

Ferro Silicon particle bakeng sa tlhahiso ea tšepe e sa hloekang

1. Theko e tlaase ebile e bonolo ho qhibiliha

likaroloana tsa ferro silicon li ke ke tsa sebelisoa indastering ea ho etsa litšepe feela empa hape le indastering ea tšepe e entsoeng ka tšepe hangata e sebelisoa lisebelisoa tsa metallurgic, haholo hobane likaroloana tsa ferro silicon li ka sebelisoa ke baetsi ba tšepe ho e-na le li-inoculants le li-nodulators, indastering ea tšepe ea tšepe, theko. ea likaroloana tsa ferro silicon e tlase haholo ho feta tšepe, 'me e qhibiliha habonolo, ke sehlahisoa sa ferroalloy se nang le bokhoni ba ho lahla.

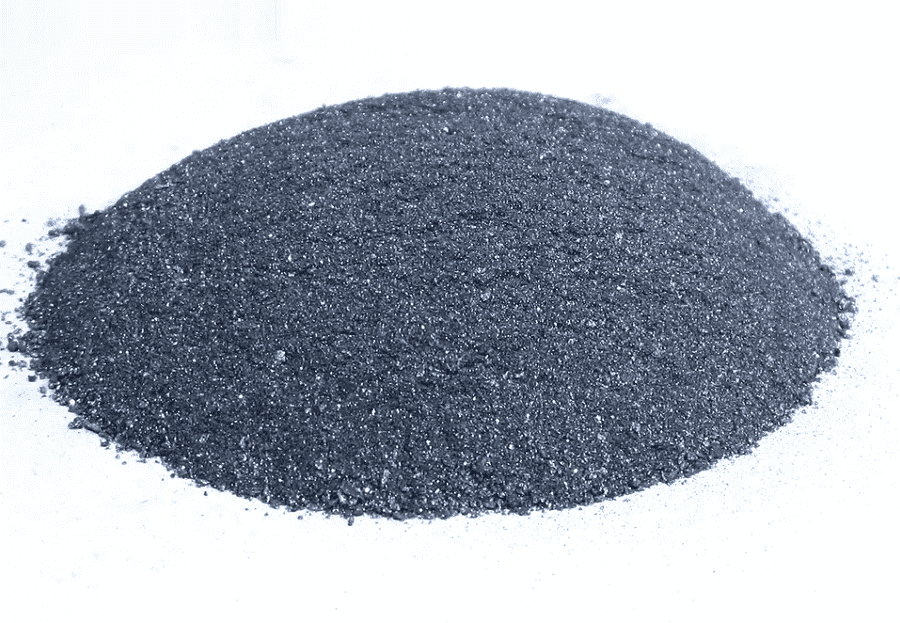

2. Uniform particle boholo

Likaroloana tsa Ferro Silicon ha li na phofo e ntle, phello e tsitsitseng ea inoculation, le tšekamelo e nyenyane ea ho hlahisa slag.Ntho e boima ka ho fetisisa ke hore li na le litšobotsi tsa liente tse ling 'me li na le litšenyehelo tse tlaase.

3. E ntle elasticity le polasetiki

Elasticity ea eona e tlase e bakoa ke ts'ebetso ea eona e tlase ea ho kobeha, 'me matla a eona a tsitsitseng a phahame ka makhetlo a' maloa ho feta a lisebelisoa tse tloaelehileng tsa tšepe tse bonolo.Karolo ea ferro silicon e boetse e na le khanyetso e ntle ea kutu, 'me lera la eona le sireletsang le ka thibela ka nepo kutu ea bokaholimo ba ho lahla.

4. Molemo machinability

Likaroloana tsa Ferro silicon li na le lisebelisoa tse ntle tsa ho sebetsa ka mochini, li ka qeta kapele mesebetsi e rarahaneng ea ho sebetsa, 'me li na le botsitso bo botle le ho hanyetsa ho roala, hammoho le bophelo bo bolelele ba ts'ebeletso.Ka mantsoe a mang, likaroloana tsa ferro silicon li na le thepa e ntle ea mochini le thepa e ka bang zero, e ba etsang lisebelisoa tse loketseng tsa ho lahla bakeng sa indasteri ea ho lahla.

5. Lintho tse babatsehang tsa thermoplastic

Likaroloana tsa Ferro silicon li na le thepa e ntle ea thermoplastic, li khona ho hanela deformation tlas'a maemo a fapaneng a mocheso o phahameng, 'me li ka boloka matla a tsona li le mocheso o phahameng, li etsa hore li tšoanelehe haholo ho sebelisoa ha ho etsoa li-castings tsa thermoplastic.

Karolo ea lik'hemik'hale

| Ntho% | Si | P | S | C | AI |

| ≤ | |||||

| FeSi75 | 75 | 0.03 | 0.02 | 0.15 | 1 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.15 | 0.5 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.1 | 0.1 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.05 | 0.05 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.02 | 0.02 |

| FeSi72 | 72 | 0.03 | 0.02 | 0.15 | 1 |

| FeSi72 | 72 | 0.03 | 0.02 | 0.15 | 0.5 |

Tlhokomeliso: Tlhahiso ea litlhaloso tse fapaneng tsa silicon calcium alloy ho latela litlhoko tsa bareki